TRB BY ROBOT

TRB BY ROBOT

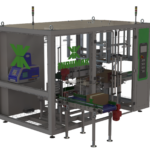

Boxing

In TRB, the Products will arrive in a cadence in a conveyor at the entrance of the Boxer, the products will be ordered to the pick-up, then the robotic system manipulate the products to the boxes, previously armed.

The box with the products will be released for the next stage of automatic closing of the upper flaps, by means of pneumatic assemblies, sensing and motorized tractors that will make the passage of the box to the automatic closing by adhesive tape or hot-melt glue, thus making the end of the complete cycle, releasing the box for the next stage of production.

– Machine with programmable logic control with interaction through HMI Touch Screen;

– Equipment monitored sensors that allow to identify the faults and levels of consumables;

– Equipment with safety according to international safety standards.

-

TECHNICAL DESCRIPTION

– Suitcase and 1/2 Briefcase;

– Maximum Product Production: TBA

– Production capacity of up to 10/15 boxes per minute;

– Voltage: 220_380V–50_60Hz;

– Closure with hot-melt tape or glue, “set with the customer”;

– Automation: Siemens;

– Sensors: Omron;

– Gearmotor: SEW;

– Pneumatic: Festo;

– Doors and protections in acrylic, with security sensors;

– Box frame system through suction cups and vacuum generating valves;

– Control through PLC & HMI Touch Screen (Setups);

– Traction of the box carried out through pull down belts;

– Structure carbon steel, with anticorrosive painting;

– Maximum width of adhesive tape up to 72mm.

Catalog - TRB BY ROBOT

Download