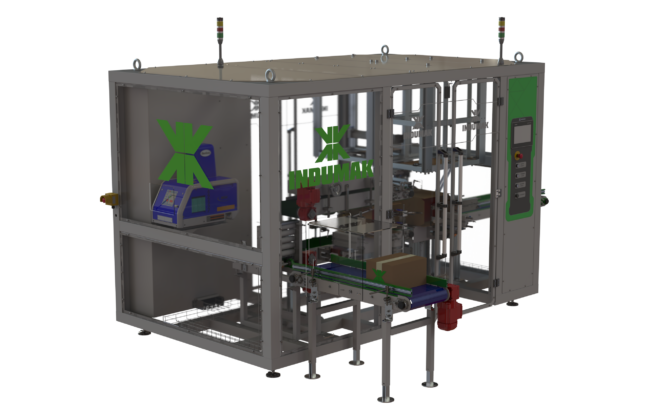

LINEAR TLN

LINEAR TLN

Boxing

The Products will arrive in a cadence on a conveyor belt at the entrance of the boxing machine, inside there is a system for organization in a forming tube, then the linear insertion system will transfer the products to the box, previously armed by pneumatic devices, sensors and pull-down belts.

The box will be released for the automatic closing of the upper and lower flaps with adhesive tape or hot-melt glue, thus making the end of the cycle, freeing the box for the next stage of production.

– Machine with programmable logic control with interaction through HMI Touch Screen;

– Equipment monitored sensors that allows to identify the faults and levels of consumables;

– Equipment with safety according to international safety standards.

-

TECHNICAL DESCRIPTION

– Suitcase and 1/2 Briefcase;

– Maximum Product Production: TBA

– Production capacity of up to 10/15 boxes per minute;

– Voltage:220_380V–50_60Hz;

– Closure with hot-melt tape or glue, “set with

the customer”;

– Automation: Siemens;

– Sensors: Omron;

– Gearmotor: SEW;

– Pneumatic: Festo;

– Doors and protections manufactured in acrylic, with security sensors;

– Box frame system through suction cups and vacuum generating valves;

– Control through PLC & HMI Touch Screen (Setups);

– Made of painted carbon steel, with anticorrosive paint;

– Maximum width of adhesive tape up to 72mm.

Catalog - LINEAR TLN

Download