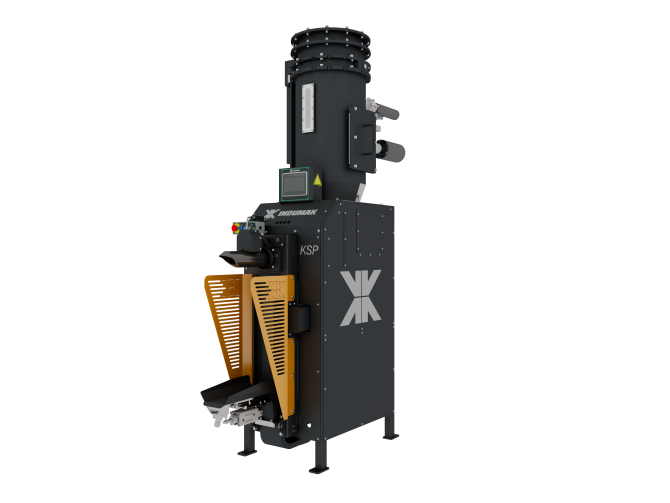

KSP

KSP

Bagging

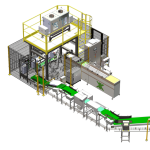

The Indumak bagger was developed to bag grains, pellets and refined.

Technology and structure to serve differente types of valve bags, suce as: raffia, kraft and plastic, with top valves, internal and external sleeve, 45 degrees and lateral.

-

SEGMENTS

Seeds, Grains, Cereals, Civil Constructions, Fertilizers, Salt, Animal Nutrition, Minerals Industry, Chemical Industry, among others.

-

MODELS

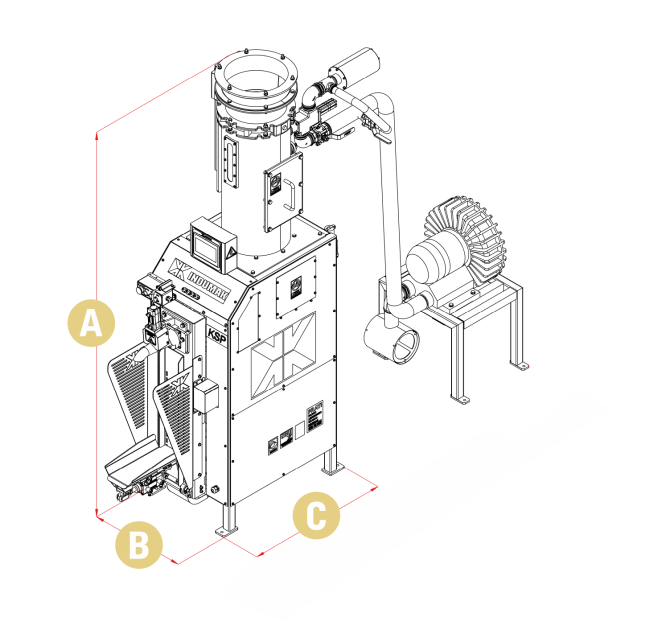

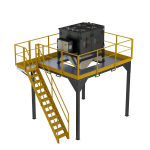

KSP – Baggers suitable for heavier products (equipped with a chambre storage space).

KSG – Bagger indicated for lighter products (in which the storage is greater). -

TECHNICAL INFORMATION

– Robust equipmente with SAE 1020 steel frame

– Structure with epoxy paint;

– Weighing capacity from 10 to 50 kg

– Weighing with control and interface on touch screen HMI

– Production data and standard deviation of weights

– Program revenue for different products and weights

– 220 V bag feeding

– Pneumatic coils voltage 24 V dc

– Working pressure 6 bar

– Average air consumption of 10 ft3 / min

– Radial compressor 7.5 hp or 10 hp high flow or Type Roots 10 hp

– Approximate weight of the equipment 580 kg

– System of withdrawal of the automatic bag

– Weight variation; meets INMETRO standards -

DIFFERENTIALS

High production, low maintenance cost, bags almost all types of products.

Catalog - KSP

Download