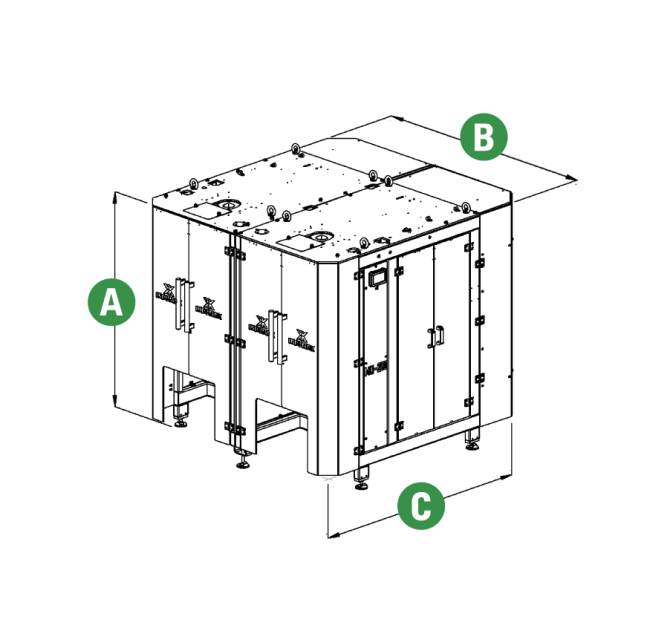

Double Automatic Packaging Machine MD-250

Double Automatic Packaging Machine MD-250

Packaging Machine

The automatic double VFFS packaging machine (Vertical Form Fill Seal) was developed to meet high production demands by integrating 2 packaging units in a single body, allowing for double the productivity in a reduced physical space, ideal for grains and granulated products. With a robust structure and cutting-edge technology, it features a servo-driven sealing system, compatibility with multiple fillers, and great flexibility for packaging formats.

Machine highlights:

High production speed: up to 160 PPM (packages per minute) in specific segments

Servo-driven sealing frame: greater precision in packaging cycles and less mechanical wear

Packages up to 250 mm wide: versatility for different types and sizes of products

Intuitive operation: simple and easy-to-configure control panel

Excellent cost-benefit ratio: ideal combination of performance, durability, and cost-effectiveness

Standard optional elements: customization according to the needs of your production line

With this automatic packaging machine, your company gains agility, reliability, and packaging standardization, optimizing the production flow and reducing setup time.

STANDARD TECHNICAL INFORMATION

– Robust equipment with SAE 1020 and AISI 304 steel structure;

– “touch screen” HMI with sealing control;

– Servo-driven horizontal sealing frame;

– Film traction via belt;

– Sealing metal with quick change;

– Motorized adjustment of the film, photocell and encoder;

– End of reel sensor;

– Film tensioning brake;

– Film unwinder.OPTIONAL

– Possibility of networking;

– Axis with quick reel change;

– Hot Stamping or thermotransfer coder;

– Eurolock, hole for gondola, and perforator;

– Forming tube for gas injection;

– Static eliminator;

– Package hole punch;

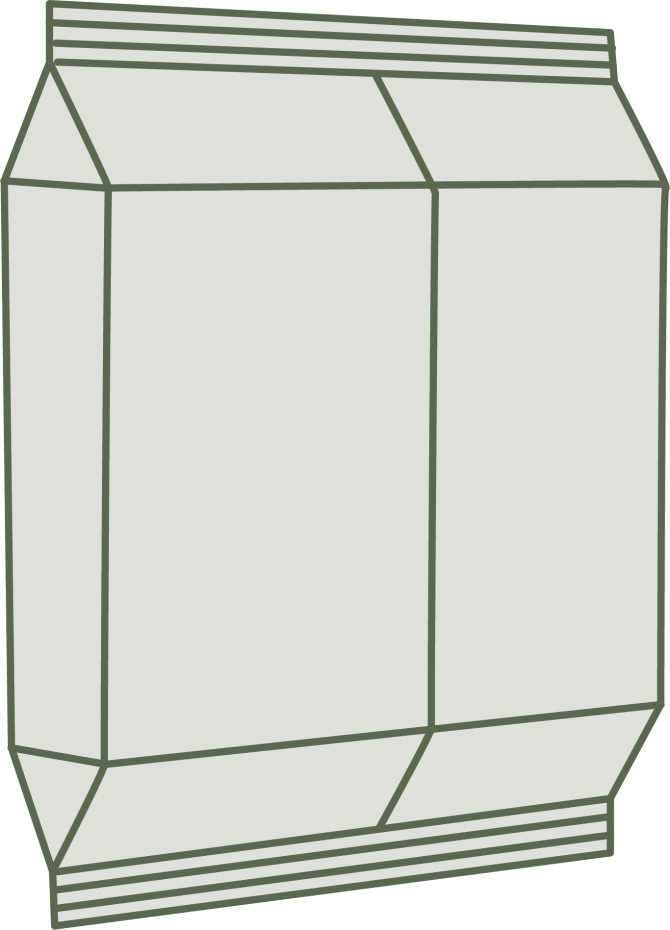

– Gusset;

– Kit to work with water-soluble coils;

– Dust exhaust system;

– Package accommodator;

– Automatic reel aligner.APPLICATION

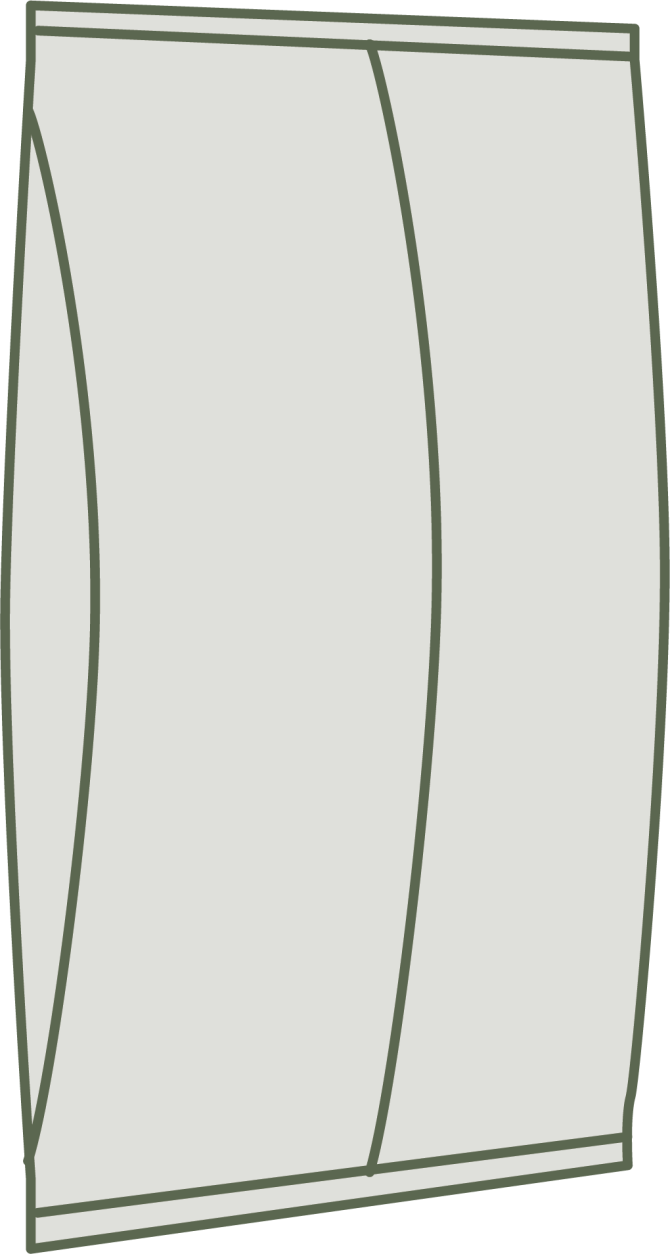

Pillow

Gusseted

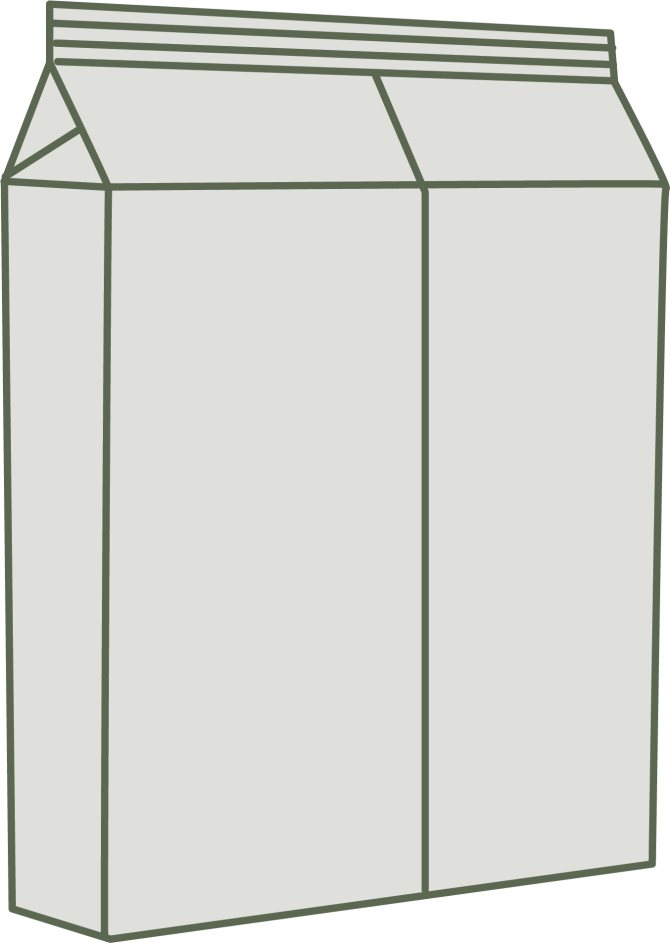

Flat Bottom

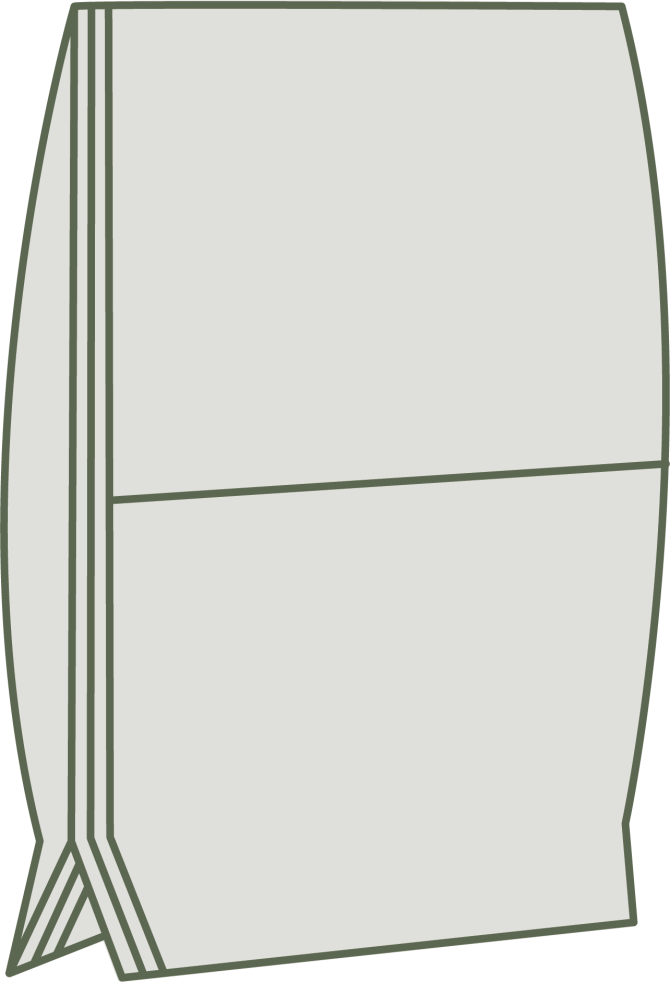

Doy pack

Catalog - Double Automatic Packaging Machine MD-250

DownloadPerguntas Frequentes

What is an industrial packer?

An industrial packer is an automated equipment designed to package products quickly, uniformly, and safely. It is commonly used in sectors such as food, pharmaceuticals, textiles, cosmetics, electronics, and chemicals, optimizing operations and reducing human error.

These machines perform functions such as:

- Sealing

- Dosing

- Grouping

- Labeling

- Vacuum packaging

In addition, they are compatible with different materials such as plastic, paper, aluminum, and biodegradable films, offering high flexibility to meet the needs of modern industry.

Why invest in an industrial packer?

In an increasingly competitive market, investing in industrial automation is essential to gain efficiency, reduce costs, and boost productivity. In this scenario, the industrial packer stands out as a strategic ally to speed up the packaging process and ensure quality at scale.

With so many options on the market, choosing the ideal model can seem challenging. However, the right decision can transform your production line. In this guide, you will discover how to choose the perfect industrial packer for your business and understand why this choice directly impacts your competitiveness.

Types of industrial packers

Learn about the main models and their applications:

1. Flow pack machine

Ideal for solid or individual products such as cookies, cereal bars, and baked goods.

2. Vertical packer

Used for powdered or granular items like coffee, sugar, and grains. Excellent for vertical packaging with automatic bag formation.

3. Blister packer

Widely used in the pharmaceutical industry to safely and securely package tablets and capsules.

Each type meets specific demands and can be customized according to the product and production volume.

Advantages of the packer on the production line

Adopting an industrial packer brings benefits such as:

- Increased productivity: higher packaging volume in less time

- Cost reduction: lower labor needs and less material waste

- Accuracy and standardization: uniform and properly sealed packages

- Product safety: lower risk of damage during transport and storage

Logistical efficiency: faster processes and deliveries